Padded knife foam, did you choose the right one?

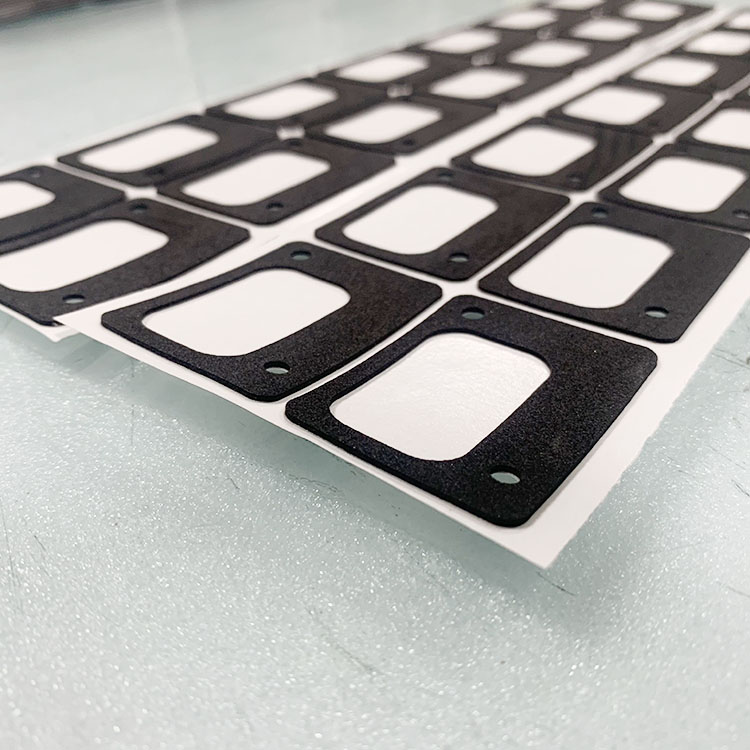

Die cutting exhibition, knife foam is primarily a rebound on the template, is to make the die cutting mould on the mould for the floor, not embedded in the can quickly leave the mold after cut the material, not take material, another role is in the pressure on the material has a fixed instant effect, especially stamping narrow spacing, close distance between the blade and the blade, In stamping die cutting of high speed, the material can not be bounced out quickly, can't completely reset, die cutting out the material will be white and the phenomenon of crease, pad knife foam as a complementary makings also play an important role, and spring rate, density and hardness is good quality pad knife foam, the three important parameters of the landscapes themselves.

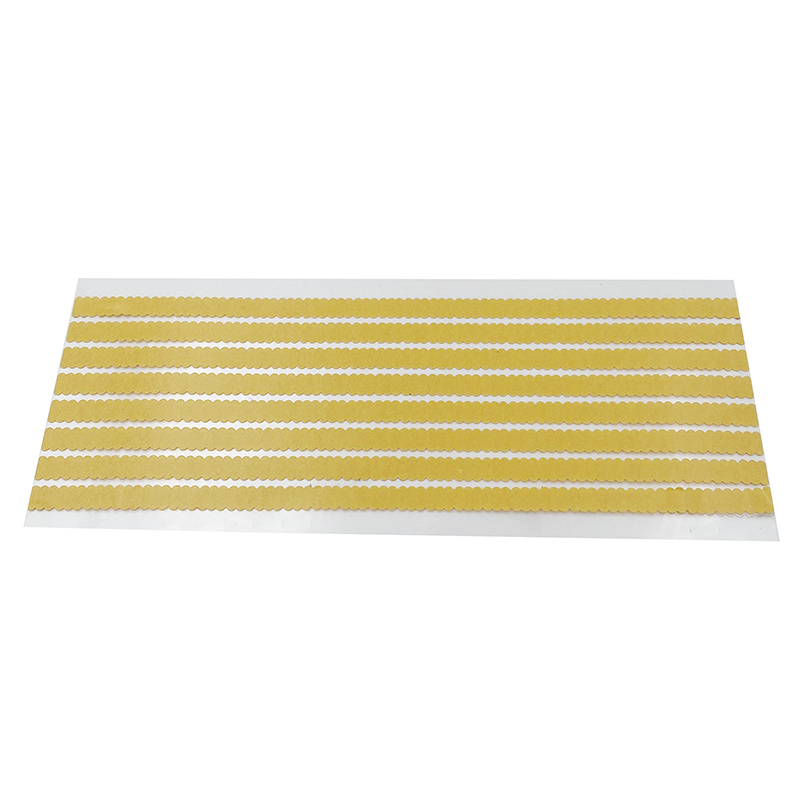

Rebound rate is a more important parameter of pad knife foam, the standard measurement is measured by "falling ball rebound tester" and usually see a knife die pad rebound, is to use the finger to pinch down to see the foam rebound, rebound good foam when the finger pinch down after release, can quickly rebound to place, finger pinch mark will disappear, When the foam rubber content is 40-100%, it will reflect a good resilience. The higher the rubber content, the better the elasticity. However, there is a certain gap between the rebound effect of synthetic rubber foam and natural rubber foam at home and that of foreign countries (such as imported materials from Japan, South Korea and Germany).

Density parameter is to reflect the number of compression ratio of die pad in stamping. Under normal circumstances, the higher the density of die pad is, the more times the stamping is carried out. The density of cushion knife foam is special. So pad knife foam density of the need to 0.25 G/CM cube above, when we choose pad knife foam, basically be to see exquisite degree of foam hole, hole size, hole if yue xiaoyue is exquisite, the higher the density, such as sofa with foam is a kind of low density foam, with his hands pressed even if the elastic is very good, but due to the low density can not fast bounce, Can not bear large pressure, can not achieve the desired effect of knife die pad.

Softness and hardness as a parameter of pad knife foam, although it is not too important in the performance of stamping, it also needs to choose the right one in overall coordination, such as with the mold and material, long-term observation can determine that 35-45 degrees pad knife foam is more suitable for stamping common materials and the use of mold, But a special materials such as PC, PE rubber mat optical plastic, the material hardness when stamping not easy mold release, so you need to choose the high hardness of knife die cushion, and such as mould blade spacing is too small, often can't afford to slug with the foam slag also need good elasticity, high hardness of the foam pad knives, such as interface too much again, easy to have a fissure mould with low foam pad the knife, The instrument used to measure the softness and hardness of foam is a hardness tester. If the foam of 3MM is placed flat on the table, it can be pressed down with force, and the hardness generally does not exceed 45 degrees.

In short, when choosing cushion knife foam, the higher the resilience, the higher the density of the knife die pad rebound effect is better, the longer the stamping life, for different materials and molds to choose different hardness, so as to ensure the more durable mold, the best effect when stamping.

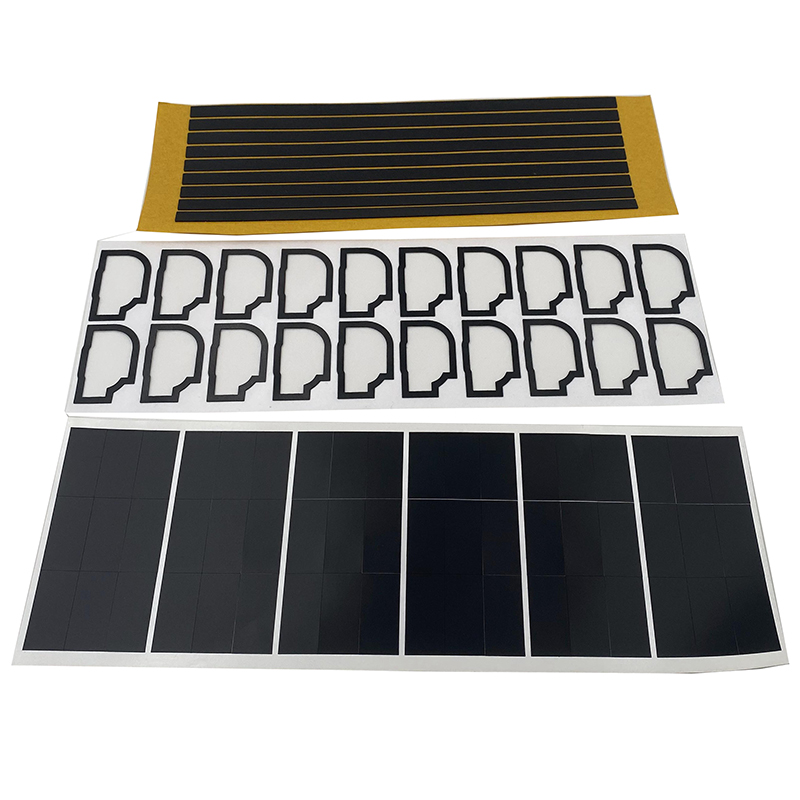

Pad knife sponge to solve the problem of sponge surface adhesive

First, a layer of release film is glued to the surface of the pad knife sponge, which not only increases the hardness of the sponge, but also reduces the phenomenon of adhesive in the stamping process;

Two, the use of cushion knife sponge with leather surface, because with leather surface is smooth and hardness is harder than without leather surface, elasticity is also very good;

Three, the use of special non-adhesive pad knife sponge, the sponge is silica gel foam, because the material is silicon, so the characteristics is not double-sided adhesive, can directly play a non-adhesive effect.

Small gap and hole plugging problem

One, can be filled with rubber bands;

Two, fill the hole with glass glue;

Three, with a very high hardness elastic super pad knife sponge.

The above is the wonderful content of die cutting exhibition to bring you, if you want to do an in-depth understanding of foam, welcome to our exhibition.

Contact: Han Lee

Phone: +86 18826132723

Tel: (0769) 8190 3062

Email: adhesive@tapedowell.com

Add: Building B, Xinyuan Industrial Park, No.11 Xialian Road, Chang 'an Town, Dongguan City