Electrical shielding is designed to prevent interference of components by high voltage field intensity. The design principle of electrical shielding is to use shielding body to minimize the distributed capacitance between the interference source and the sensor, so as to reduce the influence of the interference source on the sensor. The following with the die cutting exhibition to understand the types of conductive shielding materials.

What is conductive shielding

Electric shielding material is used between the heat source and the radiator, by eliminating the air between the heat source and the radiator, so that the heat of the electronic equipment is dispersed evenly, speed up the heat dissipation efficiency of the material. Generally all kinds of thermal interface materials need to have good thermal conductivity and surface wettability.

Conductive shielding materials mainly include the following aspects:

Conductive adhesive: the conductivity of glue adhesion agent, the conductive adhesive is a kind of dry cured or has certain conductivity adhesive, it is usually with matrix resin and conductive fillers conductive particles as main components, namely through the matrix resin adhesive effect of the conductive particles together, form a conductive path, realize the electrical connection glued materials.

As the basic resin of conductive adhesive is a kind of adhesive, suitable curing temperature can be chosen for bonding. At the same time, due to the rapid development of miniaturization and miniaturization of electronic components and high density and high integration of printed circuit board, conductive adhesive can be made into slurry and achieve high linear resolution. And conductive adhesive process is simple, easy to operate, can improve the production efficiency, so conductive adhesive is to replace lead tin welding, the ideal choice to achieve conductive connection.

Conductive shielding series of materials

Conductive shielding materials mainly include conductive foam, conductive cloth, conductive double-sided adhesive, copper foil, aluminum foil, absorbing materials and so on. Here's how these series are used:

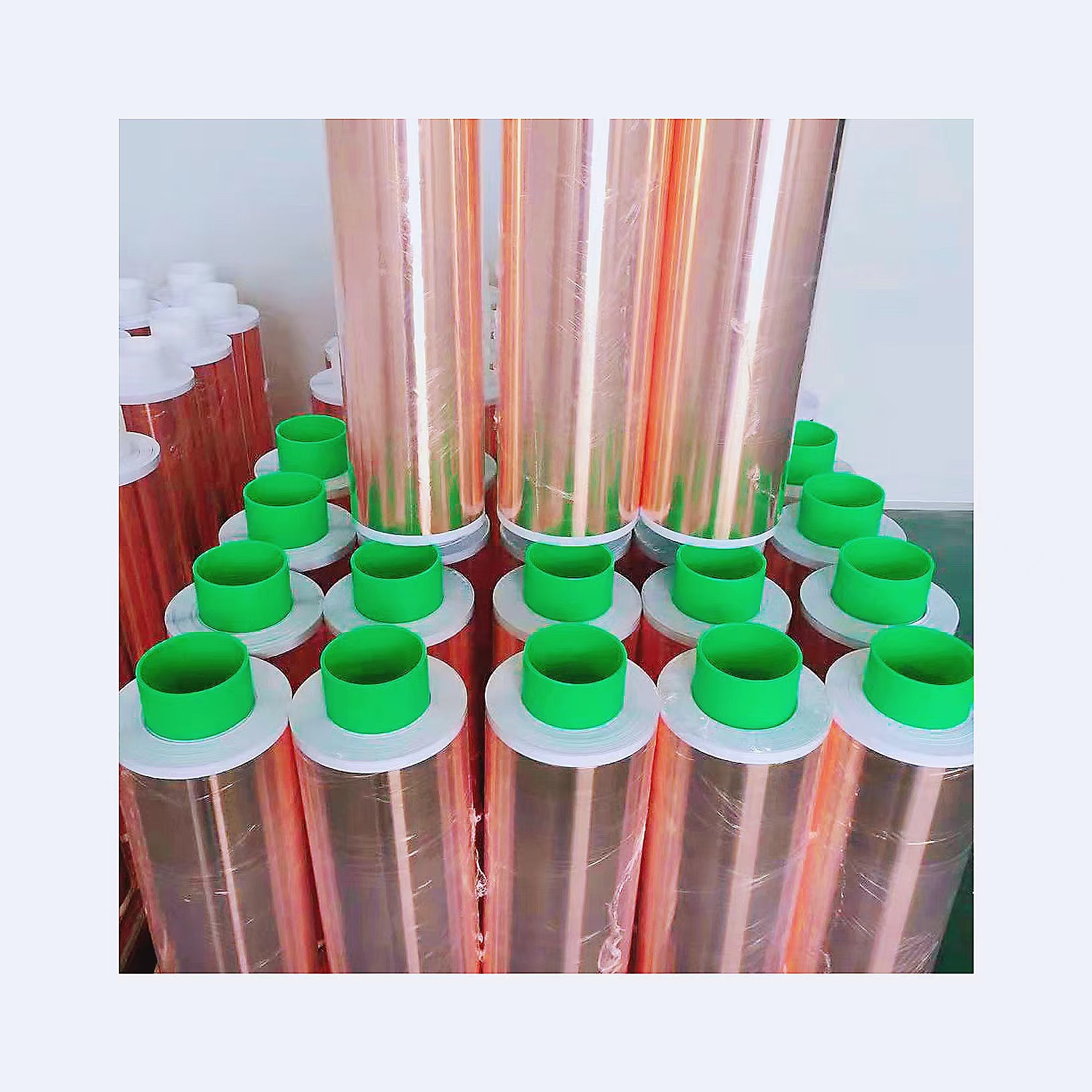

1, copper foil, aluminum foil

The utility model relates to a thin sheet material made of copper and aluminum which is directly calendered. Generally, the content of electronic products is more than 99 %. The material is soft and malleable, and has a silvery white or golden luster. But it is easy to oxidize and the color becomes dark, friction, touch and so on will change color, so the processing must have good protection measures.

Copper foil and aluminum foil are mainly used for electric conduction, heat conduction, heat dissipation, magnetic shielding, antistatic and other purposes in the electronic industry. Material hardness is not high, usually below 0.2mm, very convenient processing, and easy deformation.

Copper foil, aluminum foil application:

It is mainly used to eliminate electromagnetic interference EMI, isolate the harm of electromagnetic wave to human body, mainly used in computer peripheral wire, computer monitor and transformer manufacturers.

Copper foil, aluminum foil uses: applicable to all kinds of transformers, mobile phones, computers, PDA, PDP, LCD display, notebook computer, copier and other electronic products domestic electromagnetic shielding place.

2, conductive foam

Conductive foam is mainly divided into ordinary conductive foam and omni-directional conductive foam. It is made of elastic PU foam covered by textile fiber cloth with metal coating, which has good elasticity and conductivity. It is widely used in EMI prevention of various electronic products.

Application: suitable for the occasion that can not provide large pressure, play a good electromagnetic sealing role. Such as electronic shielding case, notebook computer, mobile communication equipment, plasma display and so on.

3, the conductive cloth

Conductive cloth is mainly divided into grid type conductive cloth and knitted conductive cloth. Plaid cloth has good electrical conductivity, good shielding effect, good processability, suitable for wrapping all kinds of regular and irregular ordinary conductive foam materials, mainly suitable for ultra-thin shielding, conductive cloth foam, conductive cloth tape, conductive cloth liner, etc., with good friction resistance. Knitted conductive cloth has good friction resistance and is easy to stamping and forming after wrapping. Its low cost and easy wrapping and forming make it the preferred material for I/O liner.

Conductive cloth: due to the conductive cloth is highly metal nylon or polyester material base material, metal pattern.it excellent electrical performance, good toughness and winding resistance at the same time, the back after the conductive adhesive is the ideal of all kinds of electrical and electronic and communication equipment shielding material, at the same time on the surface of PCB or various shielding and grounding are also very suitable.

Main types of conductive cloth:

Fabric type: plaid;

Metal coating: nickel/copper;

Conductivity: < 0.05 ohm/square;

Advantages: easy to form, strong shear resistance, anti-friction;

Characteristics of grid type conductive cloth:

1, good electrical conductivity, surface resistance is less than 0.07 ohm/square.

2, good shielding effect, shielding efficiency can reach more than 60dB.

3, good processability, soft texture, cutting without burrs, easy to cover molding.

4, suitable for packaging into all kinds of regular and irregular ordinary conductive foam preferred material.

5, mainly used in ultra-thin shielding, conductive cloth foam, conductive cloth tape, conductive cloth gasket.

6, good friction resistance, friction resistance up to 500,000 times (ASTM-D4966);

Main categories of knitted conductive cloth:

Fabric type: knitted conductive cloth;

Metal coating: nickel/copper;

Conductivity: < 0.07 ohm/square;

Advantages: low cost, suitable for I/O foam wrapping;

Characteristics of knitted conductive cloth:

1, good friction resistance, friction resistance up to 400,000 times (ASTM-D4966).

2. Low cost and easy packaging molding make it the preferred material for I/O gasket.

3. After wrapping, it is easy to stamping and forming.

4, absorbing material

Absorbing materials are mainly divided into iron oxide absorbing materials, metal powder absorbing materials, nano absorbing materials, optical transparent absorbing materials. Earlier used in the field of military stealth, this year has become more and more widely used. Absorbing materials are early used in the field of military stealth, in recent years more and more widely used in our life.

Absorbing material principle: absorbing material refers to the absorption of electromagnetic wave energy projected to its surface, and through the loss of the material, so that the electromagnetic wave energy into heat energy or other energy.

Function of absorbing material: mainly used to prevent interference, absorb electromagnetic wave, radiation, shielding and so on;

Die-cutting processing: easy to produce stratification, dust, indentation, extrusion, scratching and other undesirable phenomena.

The characteristics of absorbing material: high performance sheet absorbing material, high adhesion strength makes installation reliable, non-conductive makes very safe, outstanding mechanical properties makes easy to cut.

Application: suitable for absorbing discrete noise from PCB, RF signal plate and FFC/FPC cable signal station.

5, omnidirectional conductive foam

Omni-directional conductive foam: it is mainly composed of foam and conductive cloth coated around the foam. The whole body of the foam is provided with metal material on vacuum electroplating, which has low cost, good three-dimensional shielding effect and excellent protection performance like metal.

Features: good shielding effect, good electrical conductivity, high friction resistance, flame retardant and heat conduction.

Application: suitable for shielding of computer, TV, notebook, card reader and other products.

What are the applications of conductive shielding materials

Conductive shielding materials are used in communication equipment, network terminals, data transmission, LED, automotive, electronics, consumer electronics, medical devices, military, aerospace.

The above is die cutting exhibition xiaobian for the introduction, I hope that through this article can make you have a further understanding and understanding of it.

Contact: Han Lee

Phone: +86 18826132723

Tel: (0769) 8190 3062

Email: adhesive@tapedowell.com

Add: Building B, Xinyuan Industrial Park, No.11 Xialian Road, Chang 'an Town, Dongguan City